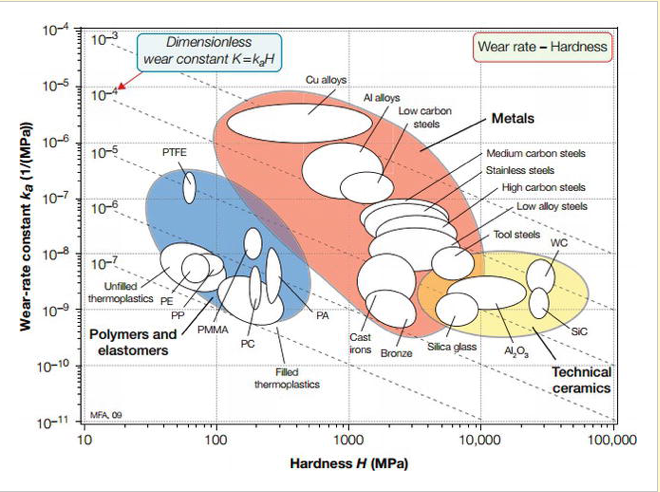

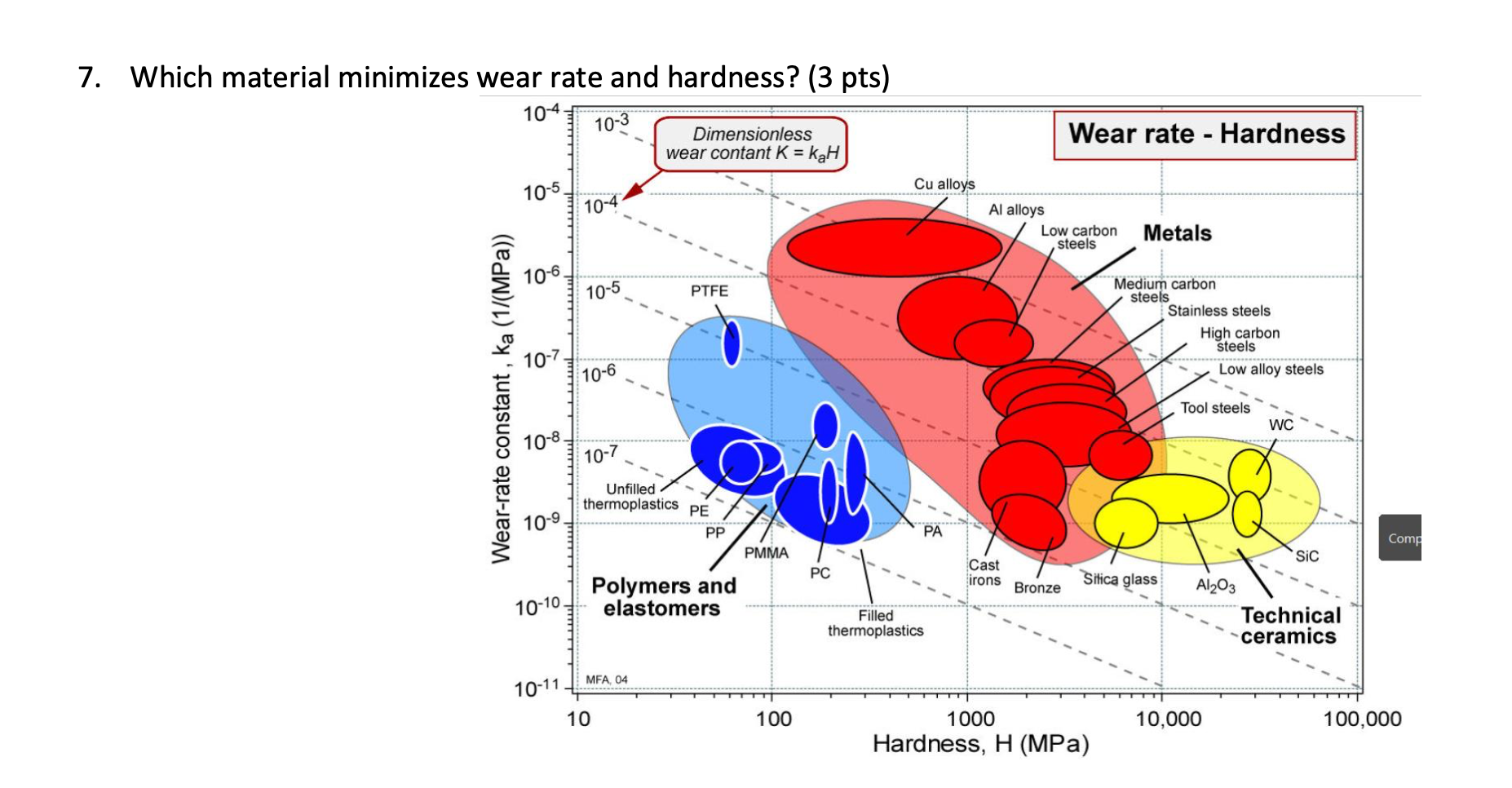

Wear rate: (a) at various loads vs. (b) the product of contact pressure... | Download Scientific Diagram

Recent Progress on Wear‐Resistant Materials: Designs, Properties, and Applications - Zhai - 2021 - Advanced Science - Wiley Online Library

Study of Friction and Wear Behavior of Graphene-Reinforced AA7075 Nanocomposites by Machine Learning

Using ANN and OA techniques to determine the specific wear rate effectors of A356 Al-Si/Al2O3 MMC | Neural Computing and Applications

Improving the specific wear rate and coefficient of friction of polyamide 6 polymer and its composite by adding wax under self‐operation conditions - Unal - 2023 - Materialwissenschaft und Werkstofftechnik - Wiley Online Library

24. Mechanism of increasing wear rate of contact wires near pantograph stopping positions of Shinkansen | R&D | Railway Technical Research Institute

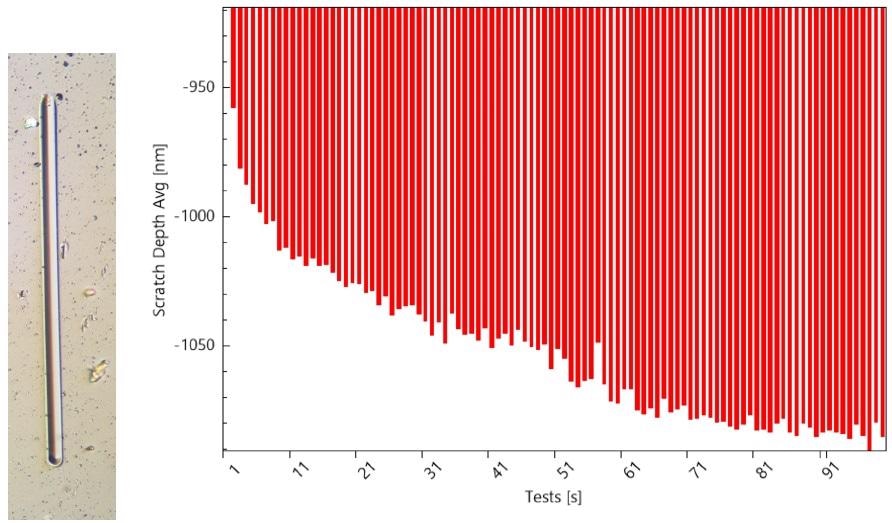

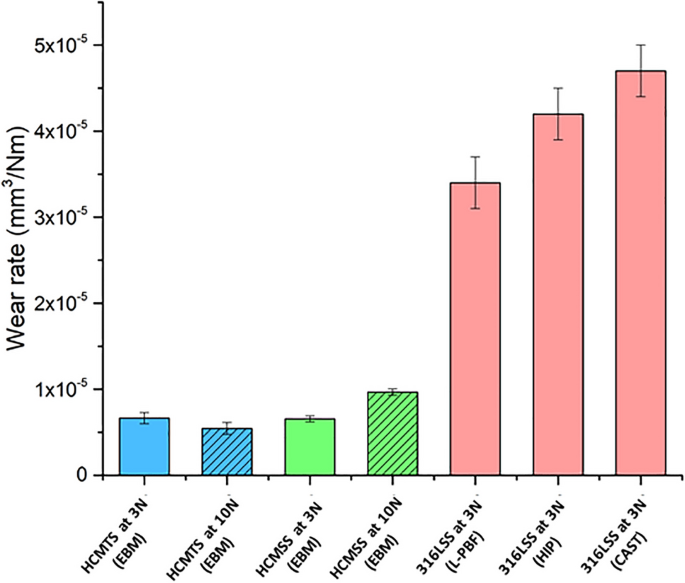

Wear resistance of an additively manufactured high-carbon martensitic stainless steel | Scientific Reports

Effect of sliding speed and hardness on wear behavior and mechanism of AISI H13 steel - Wei Jiang, Shouxing Zhu, Shuqi Wang, 2020

Wear Behavior of Brass Based Composite Reinforced with SiC and Produced by Stir Casting Process 1. Introduction

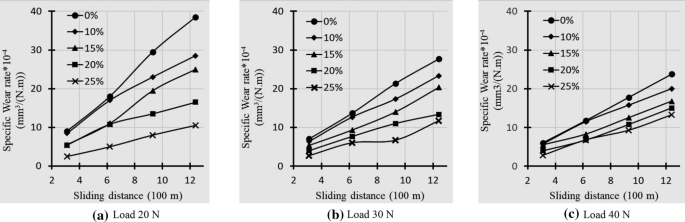

SPECIFIC WEAR RATE OF EPOXY RESIN BASED COMPOSITES REINFORCED WITH NATURAL FIBERS AND UNI-AXIAL GLASS FIBERS FOR BIO MEDICAL APP

Figure 3. Wear rate of as-cast composites with different Mg additions as (a) function of time; (b) function of load : Effect of Mg on the Wear Behaviour of as-cast Al-4.5Cu-3.4Fe in-situ

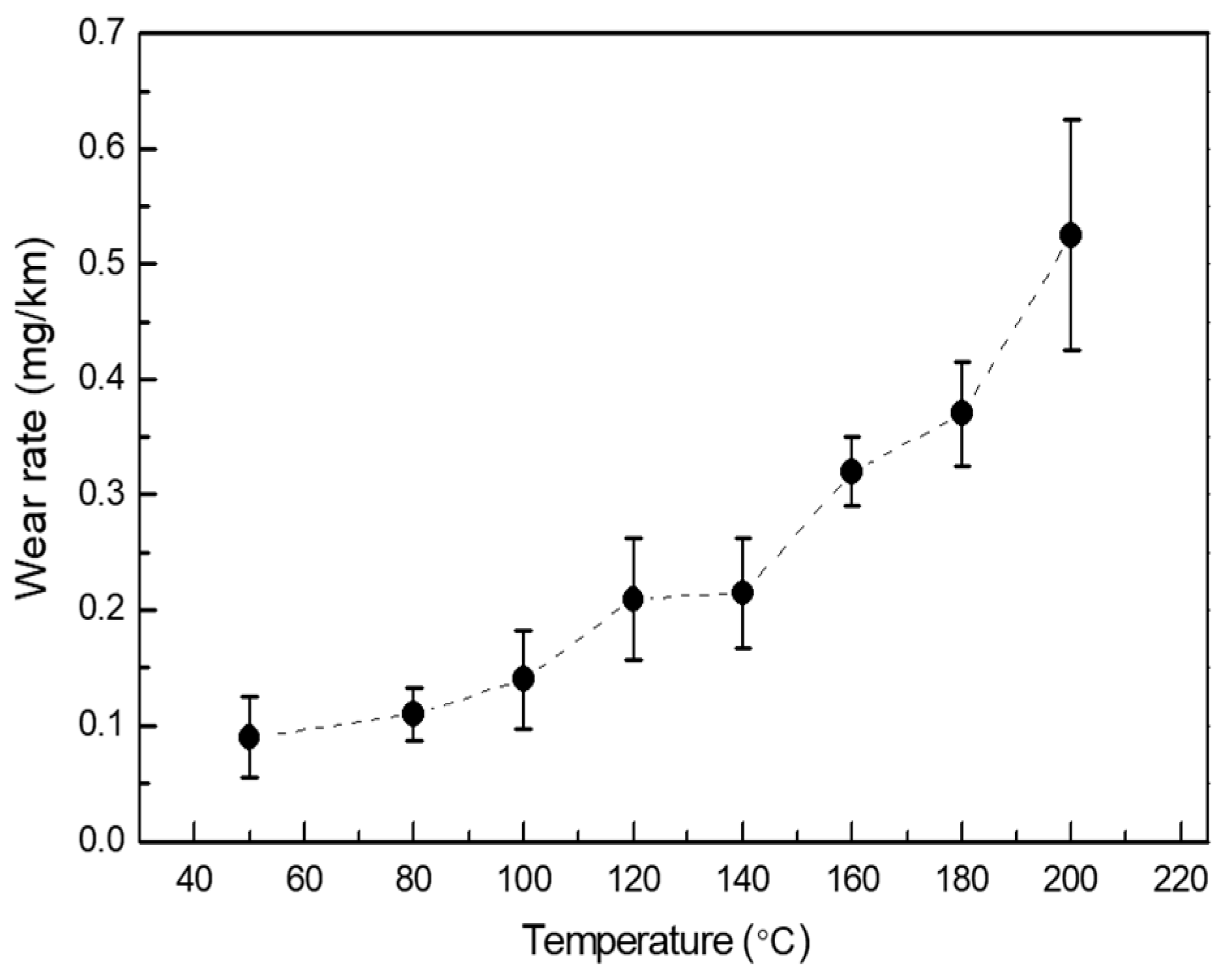

Materials | Free Full-Text | Wear Evolution of the Glass Fiber-Reinforced PTFE under Dry Sliding and Elevated Temperature